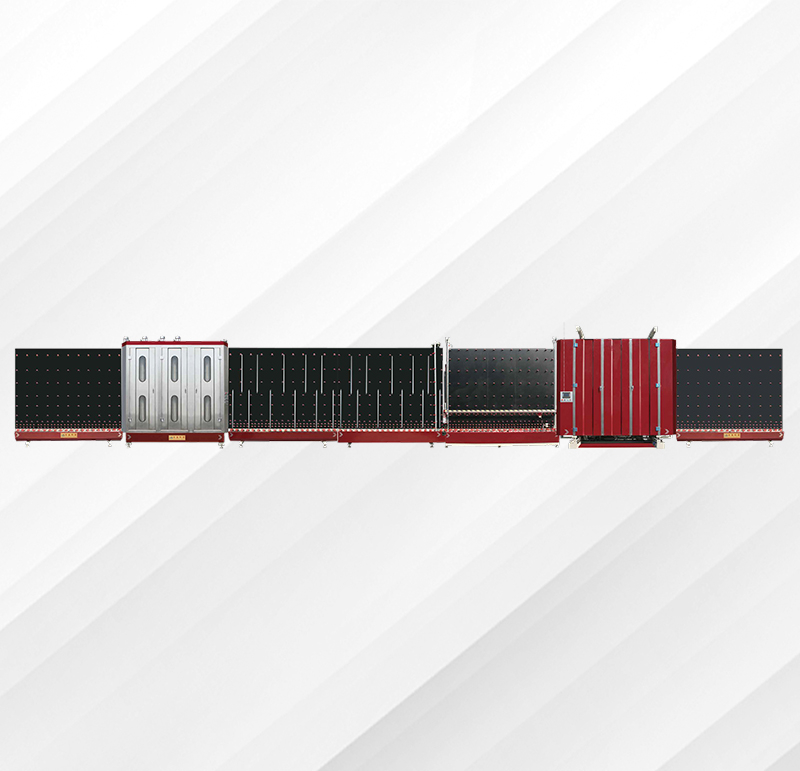

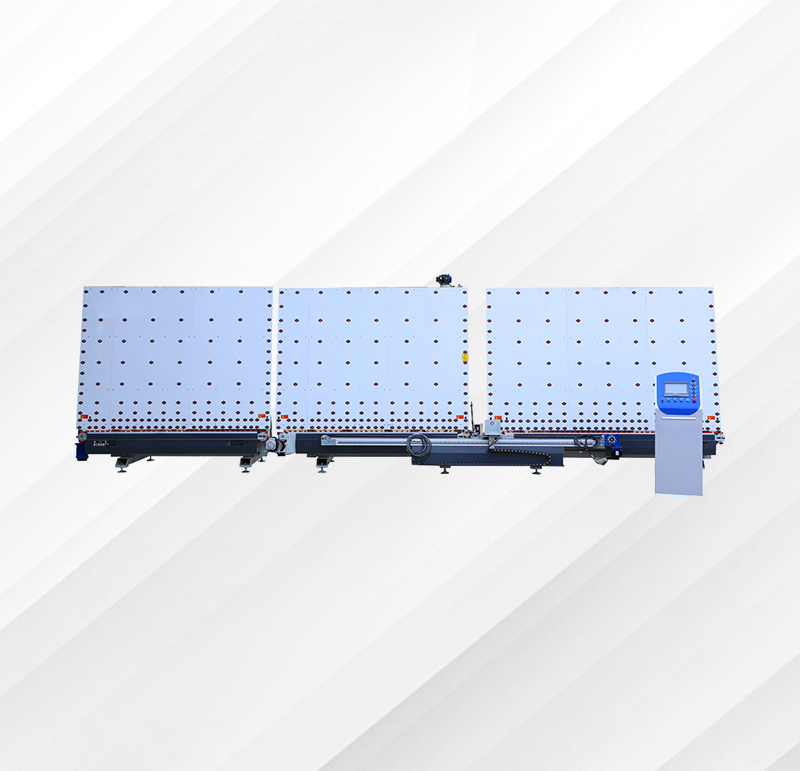

全自動丁基膠涂布機操作規程

時間:2024-12-14 來源:http://www.bjrcc.com.cn/ 發布人:昌盛機械

全自動丁基膠涂布機的操作規程主要包括開機前的檢查和開機后的操作步驟,以下是詳細的操作規程:

The operating procedures of the fully automatic butyl rubber coating machine mainly include pre startup inspection and post startup operation steps. The following are detailed operating procedures:

開機前檢查

Check before startup

確保電源安全可靠,氣源壓力符合要求(0.6-0.8Mpa)。

Ensure the safety and reliability of the power supply, and ensure that the gas source pressure meets the requirements (0.6-0.8Mpa).

檢查電、氣路是否正常,各按鍵是否正常。

Check if the electrical and pneumatic circuits are normal, and if all buttons are functioning properly.

開機操作步驟

Power on operation steps

接通電源、氣源。

Connect the power and gas sources.

將油缸升降開關調至中位,啟動液壓站。液壓站啟動穩定后,將油缸升降開關轉至“升”位置,使膠缸活塞提起,離開膠缸,返至最高位置(此動作必須在膠缸加熱到需要的溫度后進行)。

Adjust the oil cylinder lifting switch to the center position and start the hydraulic station. After the hydraulic station is started and stabilized, turn the oil cylinder lifting switch to the "up" position to lift the rubber cylinder piston, leave the rubber cylinder, and return to the highest position (this action must be performed after the rubber cylinder is heated to the required temperature).

將氣源總開關旋至“通”位置(或向上拉出),然后向上拉動擺動操作手拉閥,擺缸氣缸將膠缸活塞向后擺動,讓開膠缸口可投入膠錠。完成后,推回擺缸氣閥,并關閉氣源總開關。

Turn the main switch of the gas source to the "on" position (or pull it up), then pull the swing operation manual valve upwards. The swing cylinder will swing the rubber cylinder piston backwards, allowing the rubber cylinder port to be opened and the rubber ingot to be inserted. After completion, push back the swing cylinder valve and turn off the main air source switch.

將膠缸活塞對準膠缸中心,打開膠缸壓力開關,使活塞慢慢下壓進行入膠。

Align the rubber cylinder piston with the center of the rubber cylinder, turn on the pressure switch of the rubber cylinder, and slowly press the piston down to enter the rubber.

調整擠膠頭間距(6-16mm),并確保間隔框(條)與小壓輪、擠膠嘴中心對中性。

Adjust the spacing between the extrusion heads (6-16mm) and ensure that the spacing frame (strip) is aligned with the center of the small pressure wheel and extrusion nozzle.

啟動傳送帶,開啟加熱開關、油壓開關、膠缸活塞開關。

Start the conveyor belt, turn on the heating switch, oil pressure switch, and rubber cylinder piston switch.

調整壓噴定時器、停噴定時器、停壓定時器。

Adjust the spray timer, stop spray timer, and stop pressure timer.

將間隔框(條)置于傳送帶上,并用手壓著間隔框(條)隨傳送帶前進,保證完全壓附在傳送帶上。

Place the spacer frame (strip) on the conveyor belt and press it with your hand to move forward with the conveyor belt, ensuring complete adhesion to the conveyor belt.

關機操作步驟

Shutdown operation steps

作業完畢后,首先關掉溫控開關、膠缸活塞開關、油泵開關。

After completing the homework, first turn off the temperature control switch, rubber cylinder piston switch, and oil pump switch.

關掉傳送帶開關。

Turn off the conveyor belt switch.

關掉氣源和總電源。

Turn off the gas source and main power supply.

工藝要求

technological requirements

調整傳送帶速度(一般為4—17m/min)。

Adjust the conveyor belt speed (usually 4-17m/min).

設定擠膠座溫度(一般為120℃±25℃),設定膠缸溫度(一般為120℃±25℃)。

Set the extrusion seat temperature (usually 120 ℃± 25 ℃) and the glue cylinder temperature (usually 120 ℃± 25 ℃).

根據加工單要求調整擠頭間距,并確保間隔框與小壓輪、擠膠嘴中心對中性。

Adjust the spacing between the extrusion heads according to the processing order requirements, and ensure that the spacing frame is aligned with the center of the small pressure wheel and extrusion nozzle.

注意事項

matters needing attention

膠未加熱到需要溫度,不得啟動液壓站。

Do not start the hydraulic station until the glue has been heated to the required temperature.

嚴禁主傳動停下時調整速度。

It is strictly prohibited to adjust the speed when the main transmission is stopped.

溫度未降到40℃以下,嚴禁停止傳送系統。

It is strictly prohibited to stop the conveying system if the temperature has not dropped below 40 ℃.

遇到停電或緊急情況,使用木棒將傳送帶與擠膠座隔開。

In case of power outage or emergency, use wooden sticks to separate the conveyor belt from the extrusion seat.

請嚴格按照上述操作規程進行操作,以確保設備正常運行及人身安全

Please strictly follow the above operating procedures to ensure the normal operation of the equipment and personal safety

本文由 全自動丁基膠涂布機 友情奉獻.更多有關的知識請點擊 http://www.bjrcc.com.cn 真誠的態度.為您提供為全面的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from the fully automatic butyl rubber coating machine For more related knowledge, please click http://www.bjrcc.com.cn Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

- 雙組份打膠機旋轉伺服報警810?這樣解決快速恢復生產 2026/01/16

- 中空玻璃加工設備:打膠機機頭升降鏈條松動?這樣調節精準又牢固 2026/01/14

- 中空玻璃生產線合片段橫梁調平指南:小誤差別忽視,這樣調精準又省心 2026/01/12

- 中空玻璃加工設備的合片段橫梁高低不平?這樣調,合片精準不跑偏 2026/01/11

- 中空玻璃加工設備板壓段卡殼?輪子走玻璃不走?這樣排查超高效 2026/01/10

- 中空生產線封膠線機頭立柱不平?這樣調整,封膠均勻不返工 2026/01/05

- 中空玻璃加工設備卡殼?液壓站不起壓?卡閥問題這樣解決超省心 2025/12/31

- 全自動封膠線卡殼?貼鋁條后玻璃不走、報警?這樣解決超簡單 2025/12/31

- 冬天中空玻璃生產線出輪子灰印?這些日常難題解決辦法請收好 2025/12/30

- 全自動封膠線的“智能眼”——LOW-E識別儀,守護封膠質量的關鍵 2025/12/30

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us