單組份打膠機和雙組份打膠機的區別

時間:2021-12-01 來源:http://www.bjrcc.com.cn/ 發布人:昌盛機械

在使用的時候一般按照膠水的性能能夠劃分為單組份打膠機和雙組份打膠機。

When in use, generally according to the performance of the glue can be divided into one-component and two-component gluing machine.

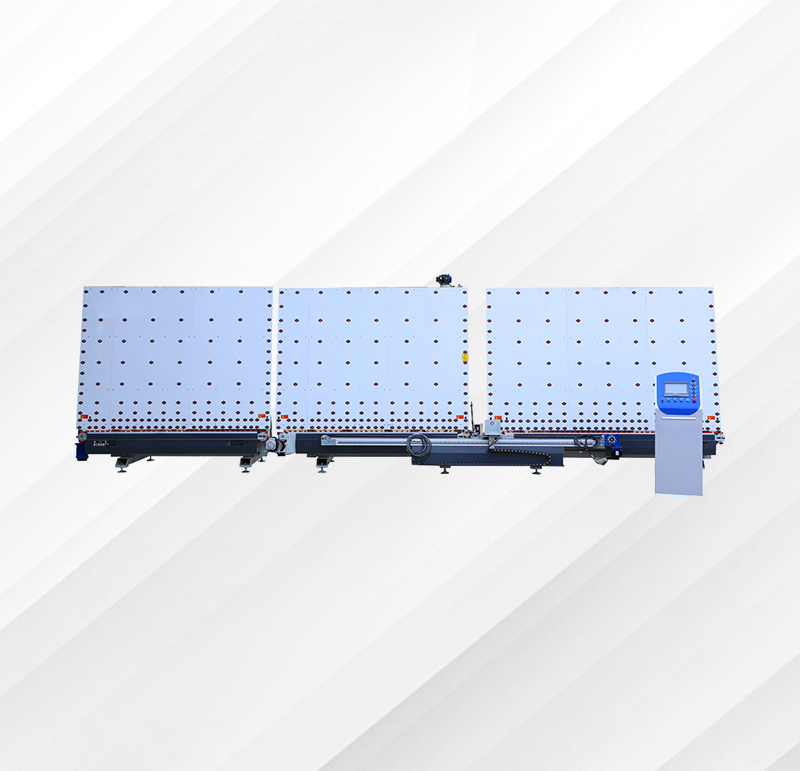

下面昌盛給大家先說說單組份打膠機,這種打膠機是比較簡單的一種設備,使用的過程比較簡單,只需要用一個壓盤把膠水抽到一定的分量,然后打進產品里面即可。另一種是雙組份膠機,其原理與我們已知的雙液點膠機差不多,工作時可根據客戶要求量身定做壓盤,壓盤需要兩個,然后將已準備好的膠桶放在兩個定制的壓盤下面,經過壓盤壓膠后,使用定量泵進行配比和混合,全部完成后在使用定量泵進行配比和混合。

The next prosperous to tell you about a single-component gluing machine, this gluing machine is a relatively simple equipment, the use of the process is relatively simple, just need to use a pressure plate to glue to a certain amount, and then into the product inside. The other is a two-component glue machine, the principle of which is similar to that of the two-liquid Glue Dispenser We know. When working, the pressure plate can be tailored according to the customer’s requirements. The pressure plate needs two, and then the prepared plastic bucket is placed under the two custom pressure plates, after the pressure plate pressure glue, the use of fixed-rate pump mix and mix, all finished in the use of fixed-rate pump mix and mix.

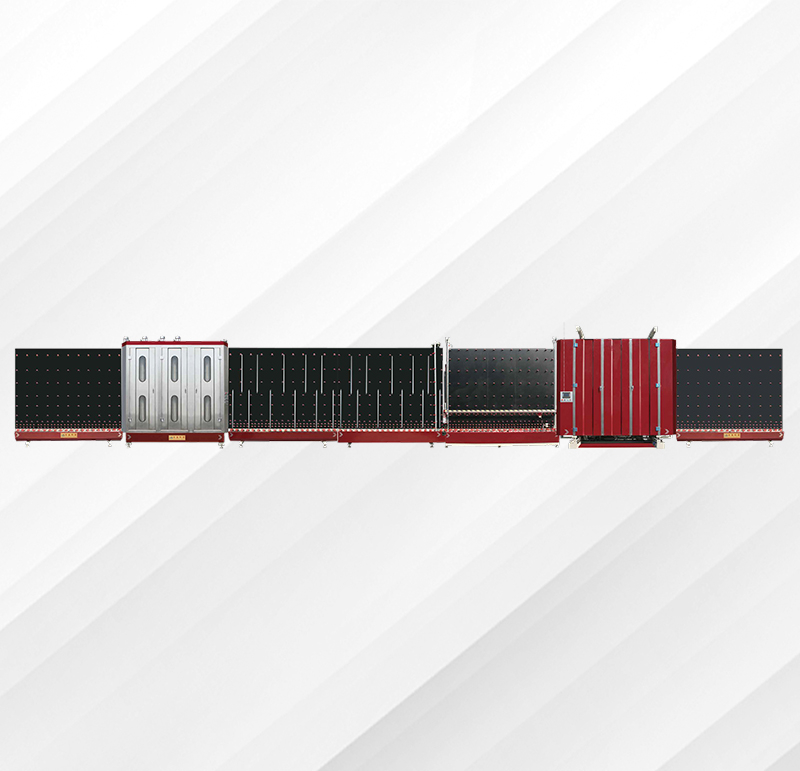

舉個簡單的例子,就知道它倆之間的區別了,比如市面上的中空玻璃打膠機一般都是采用多活塞式打膠機,因為活塞式打膠的過程比較,但由于操作不當,中空玻璃打膠機打膠線條變得不均勻,容易出現忽大忽小的狀況,因此在使用過程中經常會遇到一些不準確的問題,造成中空玻璃打膠機打膠時,打膠的線條不均勻,容易出現忽大忽小的狀況,因此經過發展和研究之后,中空玻璃打膠機的操作方法也會越來越多。

To give a simple example, we can see the difference between them. For example, the hollow glass sealing machines on the market generally use multi-piston type sealing machines, because the process of Piston type sealing is relatively professional, but due to improper operation, the Glue Line of the insulating glass glue maker becomes uneven, and it is easy to be big or small. Therefore, some inaccurate problems are often encountered in the use process, resulting in uneven glue line when the insulating glass glue maker makes glue, easy to appear large and small situation, so after development and research, insulating glass sealing machine operating methods will be more and more.

所以我們就得出了以下結論雙組份涂膠機是生產中空、幕墻玻璃的專用設備,能一次完成二道封口中 A、 B組份的混合涂膠。滿足玻璃深加工企業高效率、高合格率流水線作業的生產要求,具有較高的配比精度,是大規模生產高檔、優質中空玻璃幕墻產品的理想配套設備。

So we draw the following conclusions two-component glue machine is the production of hollow, Glass Curtain Wall special equipment, can complete two seals in a, b component of mixed glue. To meet the production requirements of high efficiency and high qualified rate assembly line in glass deep processing enterprises, it is an ideal equipment for large-scale production of high-grade and high-quality insulating glass curtain wall.

- 雙組份打膠機如何減少堵塞問題 2025/07/11

- 告別繁瑣涂膠,立式丁基膠涂布機讓效率與精度雙贏 2025/07/10

- 自動丁基膠涂布機與普通的丁基膠涂布機有什么顯著的差別? 2025/07/09

- 全自動封膠線性能上都有什么優勢? 2025/07/08

- 臥式丁基膠涂布機的規范操作流程 2025/07/07

- 中空玻璃加工設備:解密 “空氣夾層” 的誕生工廠 2025/07/04

- 雙組份打膠機的 “呼吸密碼”:解析耗氣量背后的門道 2025/07/03

- 封膠界的 “神級操盤手”:全閉環如何吊打開環與半閉環 2025/07/02

- 全自動封膠線:拆解 “智能涂膠” 的核心拼圖 2025/07/01

- 中空玻璃生產線:從原料到成品的 “規范通關秘籍” 2025/06/24

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us