雙組份涂膠機結構原理介紹

時間:2020-07-28 來源:http://www.bjrcc.com.cn/ 發布人:昌盛機械

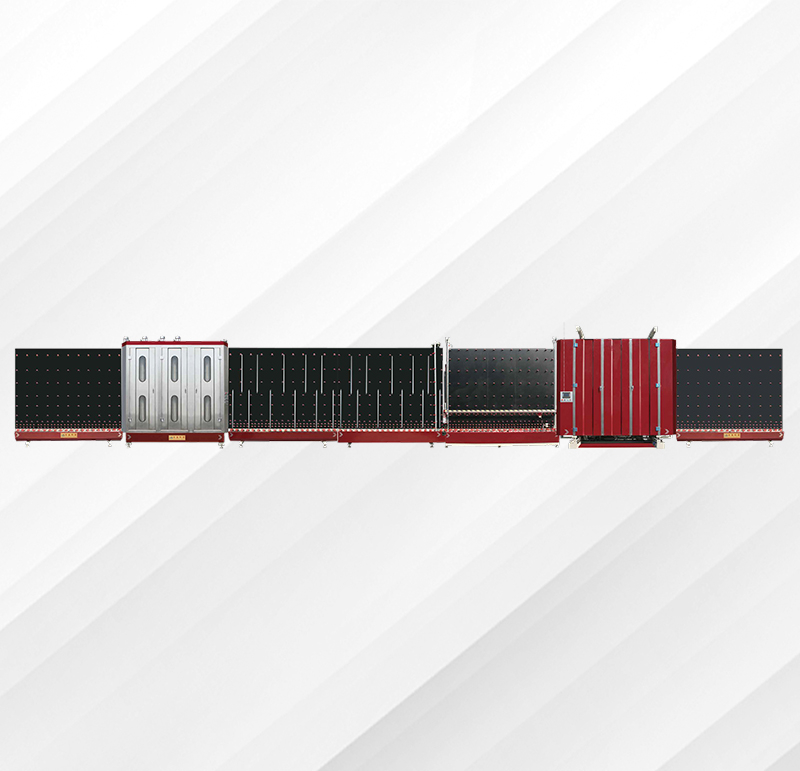

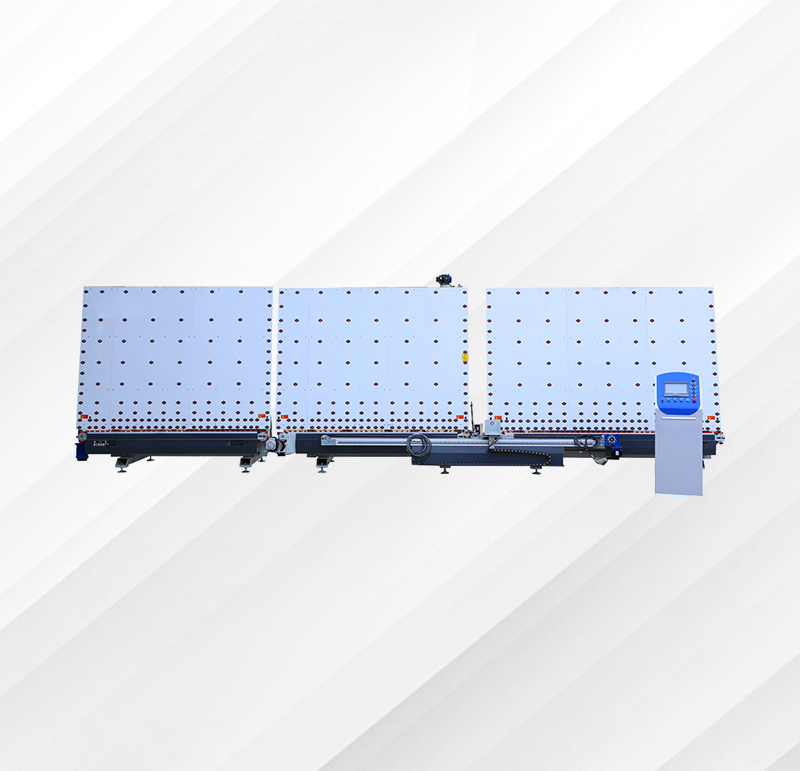

雙組份涂膠機是生產中空、幕墻玻璃的專用設備,可一次完成二道密封中A、B組份混合與涂膠。適用配比精度高的膠種,滿足玻璃深加工企業高效率、高合格率流水線作業的生產需求,是大規模生產高檔優質中空玻璃及玻璃幕墻產品的一種理想的配套設備。

The two-component gluing machine is a special equipment for the production of hollow and curtain wall glass. It can complete the mixing and gluing of a and B components in the secondary seal at one time. It is an ideal matching equipment for large-scale production of high-quality insulating glass and glass curtain wall products.

雙組份涂膠機由A、B膠泵、氣動系統、升降機構、機架等組成。現分別介紹如下:

The two-component gluing machine is composed of a and B glue pumps, pneumatic system, lifting mechanism, frame, etc. It is introduced as follows:

1.膠泵:

1. Rubber pump:

(1)A、B組份各設一個膠泵,在各自的氣馬達驅動下,分別作往復運動,將膠吸入并壓出。A、B膠泵分別與壓膠盤固定在一起,再與機架連接組成各自的系統。

(1) Each component A and B is equipped with a glue pump. Driven by their respective air motors, they move reciprocally to suck in and press out the glue. A. The rubber pump B is fixed with the pressure plate respectively, and then connected with the frame to form their own system.

(2)A、B組份的配比是通過比例杠桿進行調節:向里調節,B出膠量減少,向外調節,B出膠量增加。通過調節比例杠桿來控制B膠的出膠量,從而控制A、B膠的配比。

(2) The proportion of component A and B is adjusted by the proportional lever: the amount of glue produced by b decreases when it is adjusted inward, but increases when it is adjusted outwards. By adjusting the proportion lever to control the glue output of glue B, the ratio of glue a and glue B can be controlled.

(3)出膠量:由氣源處理器控制,逆時針調節,出膠量增加,順時針調節出膠量減小。(這里指總出膠量)

(3) Glue output: controlled by the air source processor, it can be adjusted anticlockwise to increase the glue output and decrease the glue output by clockwise adjustment. (here refers to the total glue output)

本膠泵通過比例杠桿調節A、B膠量配比,具有操作靈活,性能穩定,調節范圍大等特點。

The rubber pump adjusts the ratio of a and B glue through the proportional lever, which has the characteristics of flexible operation, stable performance and wide adjustment range.

2 . 升降機構:

2. Lifting mechanism:

A、B組份膠泵分別設一套氣動升降機構,該升降機構分別由兩個氣缸并聯組成,并通過橫梁固定連接各自的泵體。其目的之一是將兩缸的作用力通過壓盤作用在膠面上,壓力大小由調壓閥調節,一般調整在0.3MPa左右;其二,當需要更換膠桶時,氣缸可將壓盤提起。離開膠桶,以便更換新的膠桶。

A. A set of pneumatic lifting mechanism is set for component B rubber pump. The lifting mechanism is composed of two cylinders in parallel, and the pump body is fixed and connected through the beam. One of the purposes is to apply the force of the two cylinders on the rubber surface through the pressure plate, and the pressure is regulated by the pressure regulating valve, which is generally adjusted at about 0.3MPa; the other is that when the rubber barrel needs to be replaced, the cylinder can lift the pressure plate. Leave the rubber barrel to replace it with a new one.

- 雙組份打膠機如何減少堵塞問題 2025/07/11

- 告別繁瑣涂膠,立式丁基膠涂布機讓效率與精度雙贏 2025/07/10

- 自動丁基膠涂布機與普通的丁基膠涂布機有什么顯著的差別? 2025/07/09

- 全自動封膠線性能上都有什么優勢? 2025/07/08

- 臥式丁基膠涂布機的規范操作流程 2025/07/07

- 中空玻璃加工設備:解密 “空氣夾層” 的誕生工廠 2025/07/04

- 雙組份打膠機的 “呼吸密碼”:解析耗氣量背后的門道 2025/07/03

- 封膠界的 “神級操盤手”:全閉環如何吊打開環與半閉環 2025/07/02

- 全自動封膠線:拆解 “智能涂膠” 的核心拼圖 2025/07/01

- 中空玻璃生產線:從原料到成品的 “規范通關秘籍” 2025/06/24

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us